TL;DR

In Tuesday’s subscriber post, we learned about the rare earth metal industry and the PRC (People’s Republic of China) chokehold on the global supply of rare earth metals. In today’s post, we dive into neodymium magnets, one of the most important use cases for rare earth metals. Neodymium magnets are the strongest permanent magnets available on the market today, and are broadly used in devices ranging from hard drives to electric motors. The modern clean energy industry is critically reliant on neodymium magnets, giving the PRC considerable strategic leverage over the US.

Basics of Neodymium Magnets

Neodymium magnets are extremely strong and capable of holding hundreds of times their weight as the image below shows. As a result, neodymium magnets are broadly used in industry for applications in electric motors, generators, hard disks, NMR spectrometers, and many other devices. The magnets themselves are formed from an alloy of neodymium, iron, and boron (Nd2Fe14B) which forms a tetragonal crystalline lattice (source).

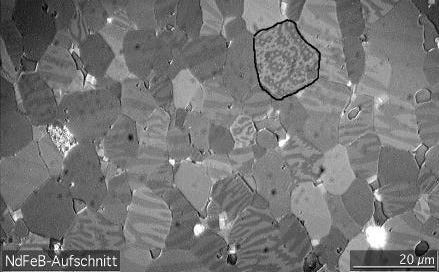

Why are neodymium magnets so strong? The tetragonal lattice Nd2Fe14B exhibits very high magnetic anisotropy, causing neodymium magnets to exhibit high resistance to being demagnetized. Like all magnets, neodymium magnets are formed out of microscopic magnetic domains (see image below) in which the magnetic moments of nearby atoms spontaneously align (due to a quantum mechanical phenomenon called the exchange interaction). The magnetic axes of these magnetic domains are aligned during the manufacturing process by exposing the raw alloy to a very strong magnetic field. The resistance of the Nd2Fe14B lattice to being demagnetized means the initial magnetization is retained readily. In addition, neodymium atoms have a larger magnetic moment than iron atoms (neodymium has 4 unpaired electrons compared with 3 unpaired electrons in iron). The larger magnetic moment gives neodymium magnets a higher magnetic saturation point, allowing them to store more than 18 times the magnetic energy of regular iron-based magnets by volume (source).

Neodymium magnets are so strong that they can even pose a health hazard by crushing fingers or other body parts caught between attracting magnets (source).

Manufacturing Neodymium Magnets

Manufacturing neodymium magnets requires considerable expertise. There are two leading methods of manufacture involving sintering and melt spinning. Sintering (as illustrated below), uses heat and pressure to compact a solid. Sintering based manufacturing starts by creating a molten mixture of the raw materials and casting this mixture into ingots. These ingots are ground into powder and then sintered into dense blocks which are subsequently magnetized (source).

The alternative manufacturing method melt-spins (see first two diagrams below) a thin ribbon of Nd2Fe14B, which is then crushed into particles and moulded into shape (see third diagram below).

As the table below shows, the PRC has a dominating lead in neodymium manufacturing. As we learned in Tuesday’s subscriber issue, the PRC has focused on building up its rare metals dominance for decades, with Deng Xiaoping famously stating, “The Middle East has oil; we have rare earths.” Ready access to neodymium and friendly governmental policy has likely spurred the thriving PRC neodymium magnet manufacturing industry. There are still notable American magnet manufacturers (such as Arnold Magnetic), but these companies are reliant on PRC rare earth supplies.

Discussion: Clean Energy and Magnets

Clean energy systems broadly rely heavily on neodymium magnets. Electric generators use strong magnets to convert from kinetic energy to electrical energy. Today’s large, efficient wind turbines require 500 kg of permanent magnets for each megawatt produced (source). Electric motors also widely use neodymium magnets, with each Toyota Prius engine requiring a kilogram of neodymium (source). AC systems have multiple electric motors and as a result make heavy use of permanent magnets. Efficient magnetic refrigeration systems are a growing research area as well (source).

The reliance of the clean energy industry on rare earth metals (and neodymium magnets in particular) has prompted concern that a focus on clean energy could play into long term PRC strategic goals (source). The reliance of the US on PRC magnetic manufacturers to meet clean energy goals gives the PRC considerable leverage over the US. The Biden administration may find it challenging to place strong sanctions on the PRC for the ongoing Xinjiang genocide unless it can overcome the PRC’s rare earth dominance (source).

Broader strategic considerations have pushed US to work towards a stronger base for domestic mining and neodymium manufacturing (source), but these efforts will likely take years to mature. Additional focus on building a strong domestic rare earth pipeline will be needed for the US to sustain its clean energy goals without finding itself held hostage by a dependence on PRC rare earths.

Highlights for the Week

https://forum.deepchem.io/t/deepchem-2-5-0-release/439: DeepChem 2.5.0 has been released! DeepChem is a library for scientific AI implemented in Python and broadly used across industry and academia. DeepChem 2.5.0 brings with it improved support for structure based drug discovery, interpretable graph convolutions, and more. (Full Disclosure: I’m the lead maintainer of DeepChem)

https://www.nextplatform.com/2021/04/12/nvidia-entangled-in-quantum-simulators/: Nvidia is entering the quantum simulator game with a new package CuQuantum.

Subscription, Feedback and Comments

If you liked this post, please consider subscribing! We have weekly subscriber-only posts on Tuesdays.

Please feel free to email me directly (bharath@deepforestsci.com) with your feedback and comments!

About

Deep Into the Forest is a newsletter by Deep Forest Sciences, Inc. We’re a deep tech R&D company specializing in the use of AI for deep tech development. We do technical consulting and joint development partnerships with deep tech firms. Get in touch with us at partnerships@deepforestsci.com! We’re always welcome to new ideas!

Credits

Author: Bharath Ramsundar, Ph.D.

Editor: Sandya Subramanian